Laser Marking Machine Offers Robust and Durable Markings

Manufacturing industries can get profit from the laser marking process in a variety of ways, including simple component identification and branding as well as total traceability to monitor and identify parts from cradle to grave. Direct component marking using a laser marking machine produces long-lasting, legible markings.

Invest in Cutting-Edge Laser Marking Machines for Great Performance

.Our laser machines are highly efficient and available at the market-leading price range. As permanent marking pioneers, we provide industries with tough, high-performance solutions they can rely on for years to come. We can also supply stainless steel laser marking machines for users who deal in the steel manufacturing industry. With Micro Industrial Solutions, you get a high-quality product with a low investment risk that has faster throughput speeds than other laser machines and so ensures increased productivity.

- Stainless Steel

- Iron

- Copper

- Gold

- Bronze

- Hard Plastic & Coated Glass

- Mild Steel

- Aluminum

- Brass

- Silver

- Platinum

- Titanium

Product Details

Product Advantages

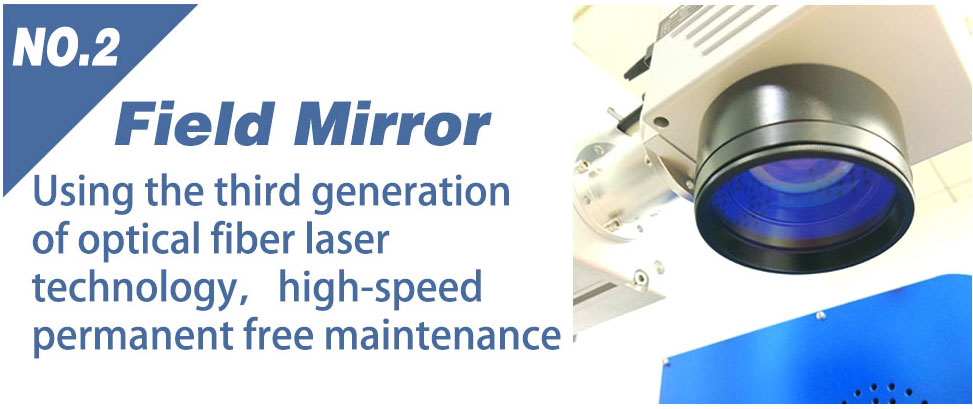

- The equipment’s steady functioning is ensured by the unique totally sealed optical circuit architecture.

- The energy-saving and efficient conversion efficiency of power and light is up to 30%.

- Small size, light weight, and easy to transport.

- High laser pulse frequency and rapid marking speed.

- No maintenance, no consumables, and low operating expenses.

- The marking programme is in Chinese and is simple to use.

- The marking material is adaptable and changeable, with lovely lines.

Optional Accessories

Technical Details

|

Model

|

Fiber laser marking machine

|

|

Power

|

20W/30W/50W/60W/100W

|

|

Laser Brand

|

Raycus/IPG/MAX

|

|

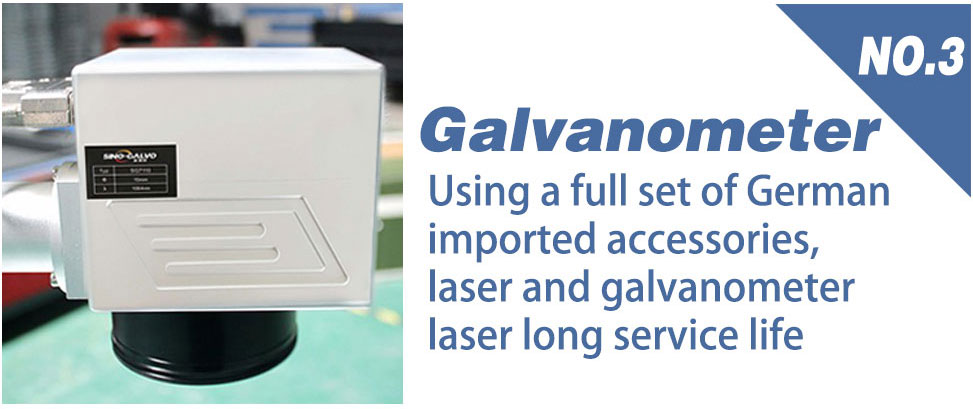

Galvanometer

|

Sino

|

|

Main board

|

Beijing JCZ

|

|

Software

|

EZCAD 2.14.10

|

|

Marking Area

|

110mm*110mm / 150mm*150mm /200mm*200mm

|

|

Marking Depth

|

≤0.5mm

|

|

Marking Speed

|

≤7000mm/s

|

|

Minimum Line Width

|

0.012mm

|

|

Life-span of Fiber Laser Module

|

100, 000hours

|

|

Beam Quality

|

M2 <1.5

|

|

Output Power of Laser

|

10%~100% continuously to be adjusted

|

|

System Operation Environment

|

Windows 7/8/10

|

|

Cooling Mode

|

Air cooling–Built-in

|

|

Temperature of Operation

|

15℃~35℃

|

|

Power Input

|

220V / 50HZ / single phase or 110V / 60HZ / single phase

|

|

Power Requirement

|

<600W

|

|

Communication Interface

|

USB

|